An entire article and thread and so far not even a single mention of RepRap? Being able to print the motors was like the single biggest hurdle left for that project!

Honestly kind of huge? 3D printing can allow for really complex geometries that just can’t be practically produced via other methods which could result in more efficient motors or designs with new and desireable torque curves.

Cool, one step closer to Von Neumann probes.

the device is equipped with four different extruders — a filament extruder, a pellet extruder, an ink extruder, and a heater — and outputted five different materials — dielectric, electrically conductive, soft magnetic, hard magnetic, and flexible.

pretty impressive

Poorly written though, saying there’s 4 extruders then only listing 3 is the kind of statement an LLM would make.

A professional would go ask the obvious question, does it have an extruder for metal (rather than metal embedded filaments, which would limit current flow).

The only mistake here is that the author switched the term “tools” for “extruders”. They did list four tools (FDM extruder, Pellet Extruder, Ink extruder, Heater).

This sounds to me much more like a human error than an LLM one, because the source material calls them “tools”.

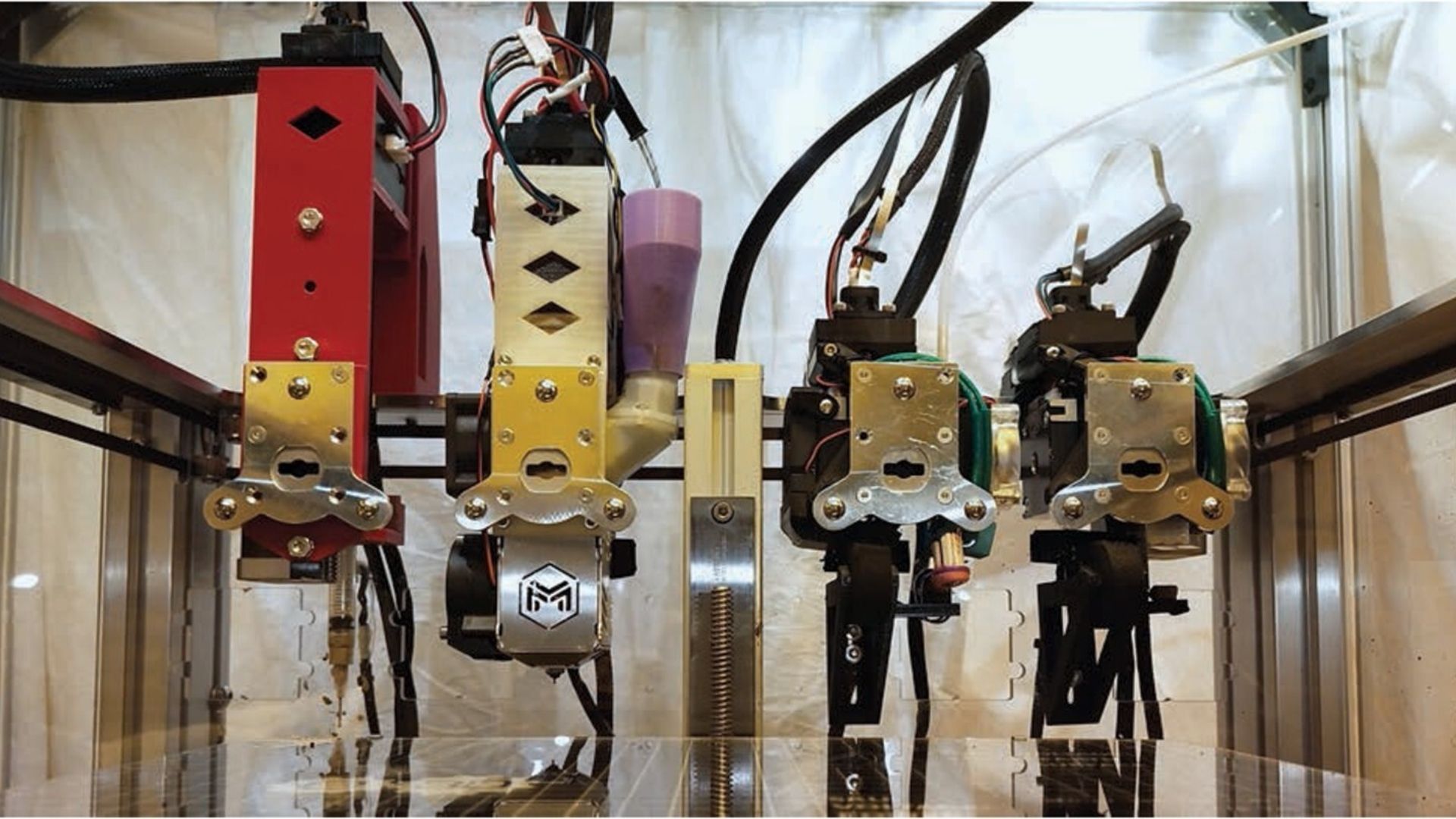

In this work, three out of the four original filament extruders were swapped for a pellet extruder, an ink extruder, and a heater. The tools that make up the final configuration of the machine are:

Filament extruder (Figure 1a): one of the original E3D Hemera direct drive filament extruders of the E3D Motion System and ToolChanger was kept in place. It features an E3D 24 V 30 W heater cartridge, an E3D thermistor cartridge, and a 0.4 mm nozzle.

Pellet extruder (Figure 1b): a Mahor v4 70 W Pellet Extruder (Mahor.xyz, Spain) was incorporated to the system to enable 3D printing from pellets. A custom case was designed and 3D printed to adapt the pellet extruder to the E3D ToolChanger. The case wraps around the extruder and provides anchor points to the E3D toolhead plate and docking port, necessary to allow the pick-up and drop-off of the tool by the robotic arm.

Ink extruder (Figure 1c): a syringe pump was custom-built from scratch, combining an E3D Hemera XS stepper motor, a lead screw, a linear rail, and custom-designed, 3D-printed parts, to enable 3D printing with inks. The syringe pump is designed to be compatible with the docking system of the E3D ToolChanger and accommodates a three-milliliter syringe that can be easily swapped, enabling seamless material exchange.

Heater (Figure 1d): an E3D Hemera extruder with its nozzle and silicon insulation sock removed was installed to enable the curing of inks on the printer bed. During operation, the ink extruder and the heater can be used sequentially: first, the ink extruder prints a pattern; immediately afterward, the heater reproduces the printing trajectory of the syringe, drying the deposited ink as it hovers over it. This strategy enables the drying of ink while printing, facilitating the deposition of subsequent layers on top of the dried ink.

https://www.tandfonline.com/doi/full/10.1080/17452759.2026.2613185#d1e378

They don’t use metal-infused filament as a conductor but conductive ink.

Might have meant 4 different heads, a heater would be the 4th one. Or just a misconception that the heater head would extrude heat?

Getting closer to replicators… and by replicators I mean…

Did you think we were in the Star Trek timeline? Fat chance!

But…

I’ve got faith of the heart.

I’m going where my heart will take me.

I’ve got faith to believe.

I can do anything.

I’ve got strength of the soul.

No one’s going to bend or break me.

I can reach any star.

I’ve got faith,

I’ve got faith.

Faith of the heart.

Well at least if we were on the Stargate timeline, we’d have:

- SG1

- the literal city of Atlantis (seriously, like, when can I move in?)

- if all else fails, plan C(4)

Mmmm… Serious putty!

Only a matter of time before these advanced printers begin printing themselves, then we’ll have to develop a 4D printer to fight them off!